How can our industry empower consumers to play a larger role in recycling and packaging sustainability in general? The answer, according to AIPIA’s communications director Andrew Manly, lies in smart packaging.

I make no apology for returning to the issue of Smart Packaging and its place in sustainable packaging development. Last time, l asked whether Smart and sustainable packaging are compatible, and hope l demonstrated where the synergies exist and where there is work to be done.

One of the main areas where a lot needs to happen is getting the consumers to buy into this whole ecosystem of recyclability and reuse by simply, returning or depositing the pack so the first two can occur!

So, it bothered me when l recently came across a report by RECOUP a charity and leading authority, which provides expertise and guidance across the plastics recycling value chain. In ‘Recyclability by Design – Back to Basics Case Study’ its CEO Stuart Foster states: “You cannot change the recyclability of a pack by passing the responsibility on to the consumer.” Hmm… l fundamentally disagree.

Whatever happened to ‘we’re all in this together’? For sure, packaging designers and converters need to be mindful of the environmental impact of the packaging and not, as this report alludes to, change the materials for what seems like sustainable reasons, which, when you dig deeper, are not at all ‘greener’. Morrison’s’ segway away from plastic milk containers to cartons is a prime example.

But if the consumer is not convinced that it’s worth it, or is simply bamboozled by it all, as l said in my previous comment, then collection and developing the infrastructure necessary is an uphill task. Tesco’s recent closure of its Loop project might be a sign of this difficulty.

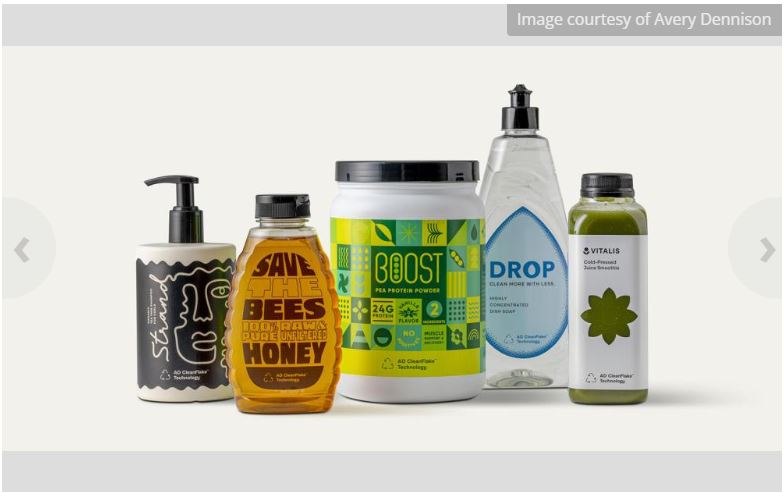

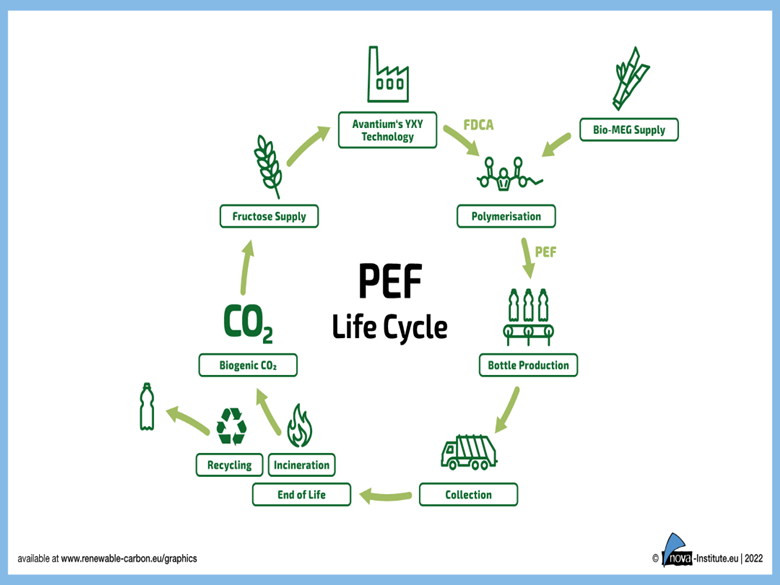

So where does Smart Packaging fit into this? Well, it can play both an active and a passive role. The passive one is already well developed, so, for example, the Holy Grail 2.0 watermarking can make sorting of different plastics much easier. But this is hardly going to get the consumer dancing in the streets, or filling up the recycle bins at their supermarket.

Better perhaps are reuse technologies, such as the 1Less system we reported on in a recent AIPIA story. Here the consumer has to do nothing but put the used, RFID-tagged container into an intelligent bin, which does the sorting automatically, sending the used pack for cleaning and reintroduction at the outlets.

But it is in the active area where l believe Smart Packaging has a crucial role to play. Connected packaging can help consumers understand the story/journey/lifecycle of the product and its packaging. If you give people a reason to take action, they often will. Of course, it would be naive to think this is, on its own, going to revolutionise the recycling sector. But it will, for sure, go some way to empowering the consumer to be a part of the solution.

It is my firm belief that we need to stop referring to ‘the war on plastic’ and start to re-educate and reassess where the gaps are in the chain, and start to ensure there is a continuous and comprehensible narrative.

Again, in my humble opinion, it does not help that there seems to be a myriad of organisations ploughing the ‘recycle’ furrow, which is very confusing. How about a more coordinated approach and less politicizing of the issue, people?

Paul East, Head of Packaging, Recycling and Design at RECOUP says: “While packaging needs to perform its main function, to protect and preserve the product, above anything else; recyclability guidelines exist to help packaging designers to make sure their packaging is designed with recycling in mind from the outset.”

While l agree with the first part of his comment, l think those offering these ‘guidelines’ need to take a long hard look at themselves and start to adopt some Smart solutions to get a coherent message across to all the stakeholders, not just the packaging sector.

This article was created in collaboration with AIPIA (the Active and Intelligent Packaging Industry Association). Packaging Europe and AIPIA are joining forces to bring news and commentary about the active and intelligent packaging landscape to a larger audience. To learn more about this partnership, click here.

Source: