Are you curious about which packaging industry trends & startups will soon impact your business? Explore our in-depth industry research on 2 907 packaging startups & scaleups and get data-driven insights into technology-based solutions in our Packaging Innovation Map!

The packaging industry is adopting smart and sustainable solutions to make product packaging more consumer-, brand-, and environmentally friendly. The major packaging industry trends that enable smart packaging are the internet of packaging, active packaging, and nanotechnology. However, since the COVID-19 pandemic has kept people in their homes, packaging from online shopping creates the serious challenge of waste production. Hence, startups and scaleups accelerate innovations around biodegradable, recyclable, and edible packaging. At the same time, the deployment of 3D printing and robotic packaging simplifies packaging processes and reduces costs for consumer companies.

Innovation Map outlines the Top 10 Packaging Industry Trends & 20 Promising Startups

For this in-depth research on the Top Packaging Industry Trends & Startups, we analyzed a sample of 2 907 global startups and scaleups. The result of this research is data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups in the packaging industry. These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2 500 000+ startups & scaleups globally. The platform quickly delivers an exhaustive overview of emerging technologies within a specific field as well as identifies relevant startups & scaleups early on.

In the Innovation Map below, you get an overview of the Top 10 Packaging Industry Trends & Innovations that impact packaging companies worldwide. Moreover, the Packaging Innovation Map reveals 20 hand-picked startups, all working on emerging technologies that advance their field. To explore custom insights, simply get in touch with us.

Tree Map reveals the Impact of the Top 10 Packaging Industry Trends

Based on the Packaging Innovation Map, the tree map below illustrates the impact of the top 10 packaging industry trends. Startups innovate to make the packaging more smart, connected, and interactive. This is done through QR codes, radio frequency identification (RFID) tags, augmented reality (AR), and the internet of things (IoT)-based food spoilage detection sensors. Increasing consumer awareness encourages companies to adopt circular packaging solutions by using biodegradable and recyclable materials such as post-consumer resins, bagasse, hemp, and polylactic acid (PLA). Digital printing on the packaging is another big trend impacting packaging supply chains. With AI-assisted robots carrying out the monotonous packaging processes of picking, placing, palletizing, and inspection, packaging automation is also disrupting the industry. Food, beverage, cosmetics, and pharma industries incorporate active packaging to tackle the challenge of product spoilage. Further, 3D printing and customized packaging enable brands to stand out and attract more consumers.

Global Startup Heat Map covers 2 907 Packaging Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 2 907 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that the United States is home to most of these companies while we also observe increased activity in Europe, particularly the UK, as well India.

Below, you get to meet 20 out of these 2 907 promising startups & scaleups as well as the solutions they develop. These 20 startups were hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Packaging Industry Trends in 2023

1. Internet of Packaging

Internet of packaging brings technological disruption to traditional packaging and allows consumers to better connect with brands. Smart packaging leverages technology such as QR codes, smart labels, RFID, and near field communication (NFC) chips. These cutting-edge solutions offer value-added benefits of security, authentication, and connectivity, making the product packaging a data carrier and digital tool. AR packaging provides companies an opportunity to better engage with customers by introducing them to a range of product content, discount codes, and video tutorials. Further, IoT devices allow brands to integrate diagnostic and indicator functionalities in their packaging, providing customers with real-time product conditions.

Langgeng Sukses Abadi Technology offers Anti-Counterfeit Solutions

Indonesian startup Langgeng Sukses Abadi Technology offers QTRUST, an anti-counterfeit solution. The startup integrates QR codes and cloud computing to allow brand owners and customers to verify product authenticity. The startup installs unique security codes on each product that allows brand owners and retailers to track items throughout the supply chain. This is done through its web-based portal and applications. QTRUST enables brands to interact with customers, deliver the correct brand story, and run customer survey campaigns. The startup’s mobile app enables users to check the product information, location of shops, transaction history, and get reward points.

TrackLegit enables Product Tracking

Slovenian startup TrackLegit builds an IoT-based smart packaging solution for product tracking. It combines near-field communication (NFC) tags on product packaging, blockchain, and a cloud software platform to track products throughout the supply chain. This allows brands to identify counterfeiting activities, detect deviations, and verify product authenticity. Besides, the startup provides a mobile app for customers to verify this supply chain data, enabling a new communication channel for customer engagement in the food, pharma, and textile industries.

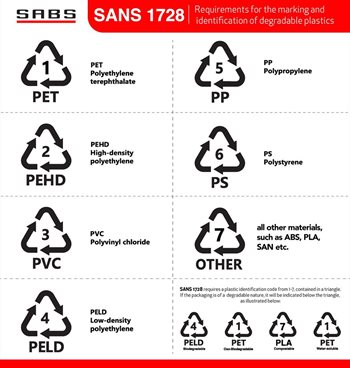

2. Biodegradable Packaging

Plastic is the most commonly used packaging material since the early 20th century. However, its slow decomposition rate causes widespread environmental problems. As consumers become more aware of the negative consequences of single-use plastic packaging, they demand eco-friendly alternatives. Biodegradable packaging and films gain traction and are suitable replacements for traditional plastic packaging. For example, starch, cellulose, PLA, polyhydroxybutyrate (PHB), polyhydroxyalkanoates (PHA), and other biopolymers. Apart from this, plant-based packaging from sugarcane, coconut, hemp, and corn starch also replaces plastic packaging. These innovations are economical for businesses to adopt and reduce the environmental impacts of the packaging sector.

OCEANIUM develops Compostable Seaweed Packaging

OCEANIUM is a UK-based startup that manufactures products from sustainably farmed seaweed. The startup procures seaweed and then utilizes refinery technology and marine science to extract maximum value out of the plant. It produces a bio-packaging material, OCEAN WARE, an all-natural, home compostable bio-packaging that replaces traditional use-and-throw packaging. The earliest version of its packaging is made to be composted for soil health or for anaerobic digestion to generate energy.

LAM’ON produces Corn-based Foil Packaging

Bulgarian startup LAM’ON produces 100% compostable and biodegradable lamination film and foil packaging. The startup produces a packaging foil made of polylactic acid (PLA), PACK’ON, derived from corn. The use of silver nanoparticles as antibacterial additives in the foil and its oxygen barrier properties make the solution suitable for food packaging. The film and foil break down in natural materials such as water, carbon dioxide, and composite. The polymer threads of the product are biaxially oriented and, hence, make it durable and less prone to tearing. Moreover, PACK’ON indicates no migration of oils and other elements, making the product safe for food and cosmetics packing.

3. Digital Printing

The process of printing on packaging comes with many challenges, some of which are accuracy, low color quality, and high labor costs. This offers the opportunity to innovate the process with digital printing, making it one of the top packaging industry trends. Unlike traditional offset or flexo printing techniques, it does not require separate plates for different prints. All the content is printed in a single pass in digital printing, making it less laborious. Modern digital printing has a limited impact on the environment as it eliminates the need for prepress procedures or additional labeling, reducing waste and inventory requirements. With less turnaround time and more flexibility, digital printing enables customized packaging for brands to cater to different subgroups of consumers. Direct thermal printing is another printing technique that uses thermal imaging and is used to print labels and flexible packaging, without the use of inks.

Flexible Pack offers Digital Printing for Flexible Packaging

Flexible Pack is a US-based startup that offers digital printing for flexible packaging. It uses an HP Indigo digital press for printing on flexible packages, pouches, shrink sleeves, and labels. The startup’s technology offers gravure-matching quality along with a wide color scale, increased productivity, and high-quality automated finishing. The technique also makes it easier to print variable data such as barcodes or QR codes. The startup also supports printing on heat-sensitive materials as well.

Copy4LessNY provides Package & Label Printing Services

US-based startup Copy4LessNY provides printing services for packaged products and labels. It offers digital printing for corrugated boxes, cartons, and films with fast turnaround times. Further, the startup offers custom printed labels for products.

4. Packaging Automation

The major challenges associated with packaging are productivity, precision, and quality control. Automating the packaging processes, such as depanning, filling, packing, and palletizing, is a big packaging industry trend. Packaging automation with the use of robotic arms and grippers not only eliminates human errors but also ensures the safe handling of delicate products. Finally, startups also develop AI-powered vision systems that take pictures of the finished goods to analyze the package quality. These vision-assisted robots automate processes such as product sorting, quality control, and inspection to increase overall efficiency.

Wootzano makes Dexterous Robotic Systems for Food & Vegetable Packaging

Wootzano is a UK-based startup that makes robotic systems to handle extremely delicate objects. The startup’s robotic system is capable of performing functions like trimming, picking, and packing fresh produce including tomatoes and grapes. The robots use machine learning algorithms to execute their tasks and adapt to changing environments. Further, LiDAR is used for inspection automation and weight estimation. The robot’s hand covered with electronic skin has high sensing capabilities, allowing it to handle delicate produce without squeezing them. It also predicts product shelf life, which, in turn, allows manufacturers to reduce wastage.

CoRobotics provides Co-bots for Packaging and Palletization

Polish startup CoRobotics builds packing robots to perform a wide range of repetitive packaging tasks. Their SmartPalletizer is an easy-to-program robotic solution that automates the entire palletizing and depalletizing process. The configuration is done through user-friendly software with palletizing parameters. It is also possible to replicate layers or set up different palletizing schemes. Additionally, the user has to enter the size and number of pallets, as well as the position of the robot and use of spacers, on the touch screen. Additionally, the SmartPalletizer configures and executes the palletization or depalletization of one or two pallets. Other features of the robot include sensors to detect the pallet and cardboard presence at the end of the line.

5. Active Packaging

According to the Food and Agriculture Organization (FAO), one-third of all the food produced for consumption is wasted globally. Food waste is a big challenge to be addressed as companies often incur huge losses because of the same. Active packaging increases the shelf life of the product and is a growing packaging industry trend, finding applications in the food, beverage, and pharmaceutical industries. For example, modified atmospheric packaging uses oxygen or ethylene absorbers and moisture regulators to keep food fresh. Another example of active packaging releases antimicrobial agents to prevent bacterial growth in the product.

SoFresh manufactures Active Packaging Films & Containers

SoFresh is a US-based packaging startup that develops food-saving packaging. The startup develops techniques for infusing food-grade natural extracts into film or containers that release controlled active vapor in the food item. Mold spores absorb the vapor, slowing down their metabolism to the point that they struggle to survive. SoFresh’s packaging products include bread and bakery packaging, over-wrap films, lid stock materials, and barrier laminations. Its active packaging solution enables companies to extend food travel life, shelf life, and consumption time so as to mitigate spoilage and wastage.

Impactful Health R&D develops Compostable Active Packaging for Fish

Canadian startup Impactful Health R&D develops a packaging solution to prolong the shelf life of fresh fish. The startup offers an active film-based technology with naturally derived anti-bacterial components. The film is biodegradable and is compliant with the Food and Drug Administration’s (FDA) oxygen transmission rate requirement. Further, it is useful in vacuum packaging applications and preserves the texture of the fish. The startup’s solution is capable of increasing the shelf life of fish by a considerable amount of time. This allows fish sellers, re-sellers, and the aquaculture industry to minimize losses.

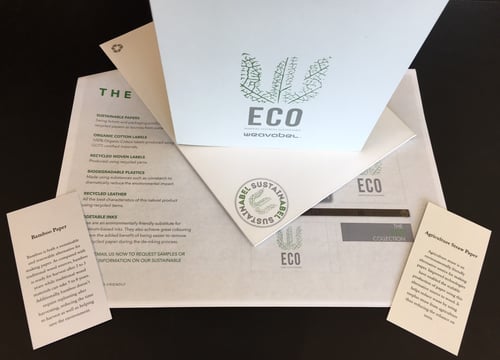

6. Custom Packaging

The appearance of a product plays a big role in attracting consumers to a product. Hence, the packaging holds as much importance as the product itself as a marketing tool for businesses. The challenge for the brands is to make the packaging eye-catching to boost sales. Making the unboxing experience more personalized and unique is the key to creating a lasting impact so that customers come back to the brand. A good example is Coca-Cola’s popular “Share a Coke” campaign which had names printed on the packaging to give it a personal touch.

PACKMOJO designs 3D Models for Custom Packaging

PACKMOJO is a Chinese startup that allows businesses to design their custom packaging on its online platform without hiring a designer. Also, the platform makes it possible for the brand to preview its design in 3D and get instant price quotes. The startup promotes sustainability by using packaging material made from 50% post-consumer waste. Further, they use eco-friendly inks like soy ink, for printing and water-based varnish instead of lamination to seal the ink.

HUIDE PACKAGING manufactures Kraft Paper Bags & Boxes

HUIDE PACKAGING is a Chinese startup that designs and manufactures custom paper packaging solutions. The startup’s in-house packaging engineers specialize in creating a structure that protects the item from damages. Also, the graphic team creates a design that aligns with the branding strategy of the company and showcases a 3D mock-up of the final design. Before the mass production of custom packaging, the startup turns the packaging ideas into tangible prototypes. It also offers fast manufacturing of custom packaging with automated machinery and 8-color, water-based flexo press printing. Finally, designing and decoration on the packaging are done with machines capable of foil-stamping, spot UV, debossing and embossing, gloss lamination, varnish, etc.

7. Recyclable Packaging

With countries banning single-use plastic, businesses now look for alternative materials for product packaging to comply with the regulations. The use of recyclable materials is one such packaging solution that enables businesses to integrate circular packaging practices. For example, post-consumer resins (PCR) are recyclable packaging material derived from post-consumer waste. Other than this, startups develop easily recyclable mono-material packaging instead of multi-layer packaging.

Boostani develops Mono-Material Packaging

Dutch startup Boostani develops mono-material barrier packaging to replace the non-recyclable multilayer packaging and reduce plastic waste. Boostani provides masterbatches and compounds for monomaterial packaging with barrier properties. It uses additives in small proportions to create a barrier, instead of different layers of plastic, which makes it recyclable. All the materials used by the startup are FDA-approved and suitable for food packaging.

Ecoplasteam derives Raw Material from Waste

Ecoplasteam is an Italian startup that makes an ecological raw material from waste. The startup produces EcoAllen, a regenerated granule based on polyethylene and aluminum. It is derived by using proprietary technology to recycle tetra packs, which are made of layers of cellulose, plastic, and aluminum. EcoAllene is an infinitely recyclable material, it is colorable, and has a glittery texture. The material has high moldability and, hence, is used to make packaging bottles. EcoAllene also finds applications in the fashion, construction, and consumer product industries.

8. Edible Packaging

Packaging follows the use-dispose model, and so largely contributes towards solid waste and ends up either in landfills or water bodies. This is why, over the last decade, businesses and consumers are moving towards sustainable packaging. The challenge for businesses is to opt for packaging that satisfies this basic functionality and also reduces or eliminates solid waste. Edible packaging is a revolutionary packaging industry trend that addresses these challenges and also enables a closed-loop for packaging. A good example is packaging made from milk protein used as casein film around food products. These films are better at keeping food fresh, compared to plastic. Also, startups making edible spoons, straws, or other cutlery items provide restaurant chains, cafes, or ice cream parlors with plastic replacements.

Decomer Technology makes Edible Packaging Material

Decomer Technology is an Estonian BioTech startup that offers a plant-based edible and water-soluble packaging material. The startup’s material is tasteless, transparent, and hypoallergenic, and finds use in food, detergent, pharmaceutical, and agriculture packaging. Its product, HoneyDrop, is honey packaged in edible packaging material. BlenDay is another product by the startup, a blendable plant-based superfood pillow pack, which is consumable by blending into smoothies. The outer layer of BlenDay is made of pectin and colorful superfood powders.

Kulero makes Edible Cutlery

Kulero is a German startup that produces edible cutlery. The startup meets the demand for disposable cutlery with its edible and sustainable cutlery alternatives. The edible cutlery is made from multi-grain flour, salt, and water. In addition, spices, herbs, or cocoa powder are used to add flavors. Kulero’s vegan spoons are durable and last 30 minutes in hot liquids or soups and 60 minutes in cold meals. The startup has managed to replace 5 million plastic spoons already. It currently offers a range of products including edible spoons, edible straws, and cups, as well as compostable bowls and plates.

9. 3D Printing

3D printing is a growing packaging industry trend that allows companies to construct different prototypes and innovate their packaging line in near real-time. Brands often experiment with packaging designs, which are costly, time-consuming, and produce waste. 3D printing technology mitigates these issues and facilitates personalized packaging, with zero contribution towards plastic waste. The technology offers greater design freedom to engineers and designers and empowers them to produce high-quality products. Additive manufacturing technology is also used by manufacturers to make prototypes of packaging machinery parts, for example, by printing robotic arms for a certain packaging line.

tForm creates Thermoformed Plastic Packaging Solutions

US-based startup tForm creates hassle-free and fast custom solutions for thermoformed packaging. To optimize packaging solutions while lowering lead times, tForm combines computer-aided design (CAD), 3D modeling, 3D printing, proprietary mold designs, and lean manufacturing techniques. The startup utilizes the most easily recyclable plastic to minimize its environmental impact. It offers packaging solutions for medical, automotive, industrial, and electronics markets. Additionally, the startup sells stock shipping trays which have industrial and medical applications via its online store.

Knurls creates 3D-Printed Packaging

Knurls is a US-based startup that produces 3D-printed packaging. The startup’s technology, KnurlPack, is used for packaging locally crafted or manufactured products in 3D printed packaging. The packaging can either be printed partly or fully around the product. The printing process uses materials like plastic, metal, or ceramic.

10. Nanotechnology

From packaging material to product safety, authentication, and tracking, nanotechnology has applications at various phases of the packaging supply chain. The use of nanoparticles mixed with polymer chains enhances package barrier properties and tensile strength. It also enables tracking and anti-counterfeiting for brands and packaging companies. Additionally, nanotech has a big impact on the food packaging industry by addressing the rising concern of food safety. Applying nanocoatings on the packaging surface keeps it safe from dirt, dust, and stains. Lastly, several types of nanosensors are useful to monitor the freshness of the food and detect any chemical changes.

CelluloTech makes Cellulose-based Materials

CelluloTech is a Canadian nanotechnology startup that focuses on cellulose-based materials. The startup’s solution replaces plastic coatings for different types of packaging with a fully renewable mono-material alternative. Its proprietary technology replaces plastics, waxes, and other non-biodegradable materials used in packaging with cellulose. Additionally, CelluloTech’s green-chemistry process, CHROMATOGENY, makes any cellulose-based material, such as paper or cotton, permanently hydrophobic.

Arylla develops Invisible Inks for Connected Products

Canadian startup Arylla provides smartphone readable invisible ink to make products traceable. Its proprietary ink uses nanotechnology and is completely undetectable by sight and touch. Label suppliers use the ink to print unique identifiers or tags with Arylla’s low-cost, small-footprint inkjet stations. Its tag platform integrates with third-party software to offer personalized customer experiences, fight counterfeit, and improve traceability. The ink is printable on different materials including woven labels, packaging, hand tags, and patches. Its use in luxury items facilitates product authentication and prevents counterfeiting.

Discover all Packaging Technologies & Startups

The Top 10 Packaging Industry Trends bring about innovative changes in the packaging industry. Soon, product packaging will feature advanced functionalities along with serving its fundamental purpose. The innovations surrounding LED embedded illuminating packaging, color-changing packaging as well as oxygen and moisture scavengers will transform the packaging industry. Further, subscription-based models for refillable or returnable packaging will significantly reduce waste production and fight single-use plastics. The use of sustainable inks, such as soy-based, water-based, and UV inks, for printing will also become more widespread.

The Packaging Industry Trends & Startups outlined in this report only scratch the surface of trends that we identified during our in-depth research. Among others, smart packaging, interactive and custom packaging will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business early on goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout relevant technologies & startups that matter to you.

Source:

https://www.startus-insights.com/innovators-guide/top-10-packaging-industry-trends-innovations-in-2021/#:~:text=The%20major%20packaging%20industry%20trends,serious%20challenge%20of%20waste%20production.

Source: Supplied

Source: Supplied

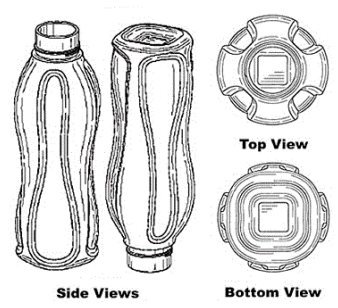

Tupperware Eco Bottles

Tupperware Eco Bottles

Tupperware Eco Bottles

Tupperware Eco Bottles Botle Buhle bottles

Botle Buhle bottles