Food and beverage brands can find alternatives to “forever chemicals” that ensure high performance of paper and paperboard packaging that also meets sustainability goals.

States like California, New York, and Maine started the year with bans going into effect for food packaging that contains chemicals of concern, specifically per- and polyfluoroalkyl substances (PFAS), also known as “forever chemicals.” This leaves packaging manufacturers with the challenge of producing sustainable and chemical-free packaging that delivers the needs of its food and beverage customers. PFAS has been found to significantly affect humans, animals, and the environment, and the presence of PFAS is now raising alarm bells as they’re used in a variety of consumer products, packaging, and clothing.

As a result, manufacturers of paper and paperboard packaging are now tasked with helping food and beverage consumer packaged goods (CPG) brands find suitable alternatives that meet their unique needs in performance — while also helping them achieve their sustainability goals with better-for-the-environment solutions. Additionally, the food industry faces unique hurdles in delivering on packaging that meets the criteria to withstand freezers, microwaves, ovens, and more.

Yet solutions that are more sustainable don’t have to impact performance. New technologies and chemistries are emerging to combine the performance criteria and PFAS-free packaging needs of the CPG industry. This demand for alternative options has put an emphasis on the barrier coatings of various wrappers, containers, single-use products, and other types of packaging. New coatings developed without the use of PFAS will need to perform just as well. But making the switch will allow packaging manufacturers to support their clients’ long-term sustainability goals.

Manufacturers must consider coating’s applications and efficiency.

Efficiency is always top of mind for packaging manufacturers, especially those in the food and beverage CPG industry. When developing sustainable packaging, identifying the coatings that will mimic the performance of previously used PFAS-infused coatings is critical. Luckily, providers of new technologies are able to design PFAS-free coatings that are still liquid and grease repellant.

When identifying the right coating for your package, the product inside must first be considered. Each food and beverage product or foodservice organization has unique needs. Moisture-sensitive fresh foods, reheatable foods, single-serve coffee cups, and even bakery paper each have a unique need. Determining the food product’s unique needs allows packaging teams to better test and select the appropriate coatings needed for a brand’s final packaging design.

Focus on plastic-free rises alongside PFAS-free packaging.

Concerns about the effects of plastic on the environment is a highly discussed topic. Just as regulation and demand has occurred for PFAS-free packaging, so too has the demand to see the elimination of plastic packaging as well. Consider how the state of California signed SB 54 last June, which includes cutting plastic packaging by 25% in 10 years. The need to reduce plastic from the food industry specifically even made its way to a global stage at last year’s COP 27 in Egypt.

Food packaging has heavily relied upon plastic but is now leading the transition to environmental-friendly alternatives. Paper packaging is a prominent solution because of its ability to biodegrade and decompose quickly. Paper also can be made from renewable resources and can be recycled which allows a continual cycle of production without using up the earth’s resources.

Packaging plays a role in CPG’s sustainability initiatives.

While PFAS-related regulations have ushered in new urgency to make shifts within packaging, it has also put further pressure on food brands to look more closely at the entire supply chain. As more companies put further emphasis on their Environmental, Social, and Governance (ESG) goals and are subject to potential ESG disclosure rules, upgrades will be made across the entire value chain.

New research shows the pay-off for the brands who make the commitment. According to McKinsey, consumer spending overall has shifted toward products with ESG-related claims. Those within packaging have the opportunity to support more sustainable, safer food packaging products that will meet brands overall ESG goals, but also support consumer demand for products making advancements to offer better options.

Manufacturers will face challenges relating to performance, production, and design. But access to new technologies and chemistries can aid them in their pursuit of a more sustainable packaging process. Alternatives like paper are accessible and meet regulations and consumer expectations, which is why it is important to communicate eco-friendly changes that are made. Packaging is a vital part of any product and manufacturers need to acknowledge and meet expectations in the evolving packaging industry.

States like California, New York, and Maine started the year with bans going into effect for food packaging that contains chemicals of concern, specifically per- and polyfluoroalkyl substances (PFAS), also known as “forever chemicals.” This leaves packaging manufacturers with the challenge of producing sustainable and chemical-free packaging that delivers the needs of its food and beverage customers. PFAS has been found to significantly affect humans, animals, and the environment, and the presence of PFAS is now raising alarm bells as they’re used in a variety of consumer products, packaging, and clothing.

As a result, manufacturers of paper and paperboard packaging are now tasked with helping food and beverage consumer packaged goods (CPG) brands find suitable alternatives that meet their unique needs in performance — while also helping them achieve their sustainability goals with better-for-the-environment solutions. Additionally, the food industry faces unique hurdles in delivering on packaging that meets the criteria to withstand freezers, microwaves, ovens, and more.https://acd06921a3687c0ba20807c9d7a55870.safeframe.googlesyndication.com/safeframe/1-0-40/html/container.html

Yet solutions that are more sustainable don’t have to impact performance. New technologies and chemistries are emerging to combine the performance criteria and PFAS-free packaging needs of the CPG industry. This demand for alternative options has put an emphasis on the barrier coatings of various wrappers, containers, single-use products, and other types of packaging. New coatings developed without the use of PFAS will need to perform just as well. But making the switch will allow packaging manufacturers to support their clients’ long-term sustainability goals.

Manufacturers must consider coating’s applications and efficiency.

Efficiency is always top of mind for packaging manufacturers, especially those in the food and beverage CPG industry. When developing sustainable packaging, identifying the coatings that will mimic the performance of previously used PFAS-infused coatings is critical. Luckily, providers of new technologies are able to design PFAS-free coatings that are still liquid and grease repellant.

When identifying the right coating for your package, the product inside must first be considered. Each food and beverage product or foodservice organization has unique needs. Moisture-sensitive fresh foods, reheatable foods, single-serve coffee cups, and even bakery paper each have a unique need. Determining the food product’s unique needs allows packaging teams to better test and select the appropriate coatings needed for a brand’s final packaging design.

Focus on plastic-free rises alongside PFAS-free packaging.

Concerns about the effects of plastic on the environment is a highly discussed topic. Just as regulation and demand has occurred for PFAS-free packaging, so too has the demand to see the elimination of plastic packaging as well. Consider how the state of California signed SB 54 last June, which includes cutting plastic packaging by 25% in 10 years. The need to reduce plastic from the food industry specifically even made its way to a global stage at last year’s COP 27 in Egypt.

Food packaging has heavily relied upon plastic but is now leading the transition to environmental-friendly alternatives. Paper packaging is a prominent solution because of its ability to biodegrade and decompose quickly. Paper also can be made from renewable resources and can be recycled which allows a continual cycle of production without using up the earth’s resources.

Packaging plays a role in CPG’s sustainability initiatives.

While PFAS-related regulations have ushered in new urgency to make shifts within packaging, it has also put further pressure on food brands to look more closely at the entire supply chain. As more companies put further emphasis on their Environmental, Social, and Governance (ESG) goals and are subject to potential ESG disclosure rules, upgrades will be made across the entire value chain.

New research shows the pay-off for the brands who make the commitment. According to McKinsey, consumer spending overall has shifted toward products with ESG-related claims. Those within packaging have the opportunity to support more sustainable, safer food packaging products that will meet brands overall ESG goals, but also support consumer demand for products making advancements to offer better options.

Manufacturers will face challenges relating to performance, production, and design. But access to new technologies and chemistries can aid them in their pursuit of a more sustainable packaging process. Alternatives like paper are accessible and meet regulations and consumer expectations, which is why it is important to communicate eco-friendly changes that are made. Packaging is a vital part of any product and manufacturers need to acknowledge and meet expectations in the evolving packaging industry.

The solution is replacing PFAS packaging.

With PFAS historically being the default solution to withstand water, grease, and temperature fluctuations, a new sustainable solution has to become its replacement. Innovative companies are inciting change for manufacturer and CPG brands by matching these performance needs without the use of toxic chemicals.Impermea Materials

As food and beverage manufacturers steadily move away from PFAS in their packaging to avoid health, sustainability, and environmental risks, they must look towards solutions that are safer, durable, and ultimately more cost effective. Through creative designs with ordinary materials, brands from all industries will be able to work with safer solutions to revolutionize packaging on an industrial scale.

Source:

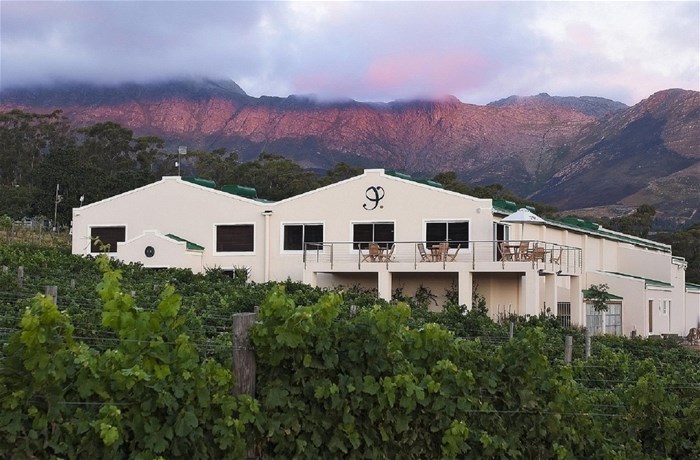

Journeys End Vineyards Cellar

Journeys End Vineyards Cellar

Heinz Brazil’s new recycled PET sauce bottles are estimated to save around 700 metric tons of virgin material each year.

Heinz Brazil’s new recycled PET sauce bottles are estimated to save around 700 metric tons of virgin material each year. Clover Sonoma’s new milk jugs are made with Envision’s EcoPrime food contact-approved rHDPE.

Clover Sonoma’s new milk jugs are made with Envision’s EcoPrime food contact-approved rHDPE.