Xampla, which produces plastic-free biodegradable packaging solutions using “100% natural”, chemically unaltered plant materials, made a landmark announcement towards the end of last year. It will now be working with 2M Group in a bid to scale up the production and distribution of its solutions. Stanley Mitchell, the company’s head of business development, tells us more.

It would be great if you could give us a brief overview of Xampla and the innovation it has created. How does it compare with conventional materials in terms of functionality and carbon emissions?

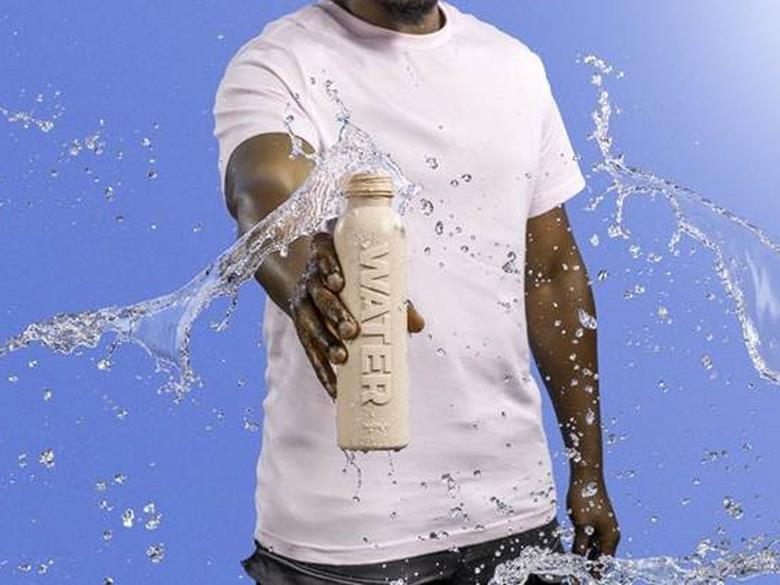

Xampla’s technology and materials are the product of more than 15 years of fundamental protein research at the University of Cambridge. This year, Xampla took a huge step in the scale-up and commercialisation of its products by launching Morro – its first consumer brand.

Morro is a high-performance, plant-based material that is 100% natural and biodegradable. Made from chemically unaltered plant materials, with no harmful chemical agents or crosslinking, Morro materials return back to nature after use, biodegrading completely in all different end of life scenarios.

The high-performance material provides excellent barrier properties, meaning it can replace conventional materials, such as single-use plastics. However, unlike plastic, it biodegrades at end-of-life – providing the experience consumers are used to, without the pollution.

The material is a drop-in solution for manufacturers and works on existing machinery and manufacturing processes, enabling brands to make a simple swap to a sustainable alternative.

It’s been a couple of years since we last spoke with Xampla. What’s changed in your industry space since the last time we spoke, and what has Xampla’s journey looked like in the intervening years?

Even within the last two years, much more regulation has come into place to phase out plastics across the world. The recent single-use plastic ban in the UK demonstrates the increasing appetite for plastic-free alternatives both amongst brands and regulators.

However, the marketplace for alternatives can be confusing to navigate, with an array of greenwashing claims.

As a result, we have seen increased interest in truly sustainable and simple-to-understand solutions. Morro materials are made just from plants, so will fully biodegrade wherever they end up. Consumers do not want to navigate complicated end-of-life processes, so this makes it a simple swap.

Part of that change is also about material availability, and Xampla has made incredible progress in the past 24 months. We have signed our first large-scale manufacturing agreement with UK based 2M Group of Companies to ramp up production to the kiloton scale. This is an incredible landmark not just for Xampla as a company, but for the broader biomaterials industry: showing that breakthrough new materials like Morro are accessible and commercial in scale.

One major change we’ve noticed is that a huge number of flexible materials made from non-traditional sources have been launched since then. What separates Xampla from the crowd?

We are a leading company engineering plant proteins and other natural polymers as a drop-in, high-performing next-generation material that can eliminate some of the most polluting forms of plastic.

Other plant-based replacements are based on plant polysaccharides (for example starches), which require chemical modification to match the high performance we can achieve with proteins. Made from plants, Morro requires no harmful chemical additives or crosslinking, meaning it can biodegradable completely at end-of-life.

At Xampla, we also produce our materials with an agnostic approach. This means that we use a variety of waste stream-derived plant-based feedstocks and tailor them to specific applications, rather than focusing on a singular source.

What does Xampla’s new partnership with 2M mean for the company in real terms?

Our partnership with 2M Group of Companies is focused on industrialisation and process, and scaling up the manufacturing of Morro materials.

Xampla will continue to develop its plastic-free technology solutions, with 2M manufacturing Morro materials at scale from its manufacturing facility in Milton Keynes. This will enable 2M to leverage their network and expertise in chemical manufacturing and distribution and expand their offering into the packaging industry through the Morro Coating platform.

In addition, 2M are well connected to leading CPG brands in the personal care and HI&I industries that will provide an excellent launch pad to bring Morro materials directly into these segments of the market, helping brand owners eliminate unnecessary plastic from their supply chain.

This agreement is a real landmark for both companies and shows what can be done when established industry players and innovative startup companies work together to achieve change.

Your company, along with a number of other organisations within the “natural polymers” space, encouraged policymakers at INC-3 to recognize natural polymer materials as valuable assets in combating plastic pollution. Could you tell us a bit more about it? How would you reflect on INC-3 now that it had concluded?

As a member of the Natural Polymers Group, Xampla are advocating for the broader recognition of natural polymer materials as valuable assets in addressing plastic pollution.

Our focus is on encouraging policymakers to support the acceleration of industry development and incentivise the adoption of plastic-free substitutes as mainstream solutions, and expansion.

As a collective, our key proposals include the need for a clear definition for plastic and non-plastic substitutes, as well as an expanded criteria for circularity – both of which should acknowledge the end-of-life benefits of natural polymers. To achieve these goals, alongside the Natural Polymers Group, Xampla have called for ambitious policies and incentives aimed at reducing the use of plastics, where alternatives are viable. Our objective is to create a regulatory environment that fosters the production and use of natural polymer solutions derived from abundant renewable resources.

We are looking ahead to continued discussions at INC-4 in April to see whether any of these aspects will be addressed.

Source:

https://packagingeurope.com/features/whats-next-for-xamplas-plastic-free-100-natural-packaging-materials/10836.article