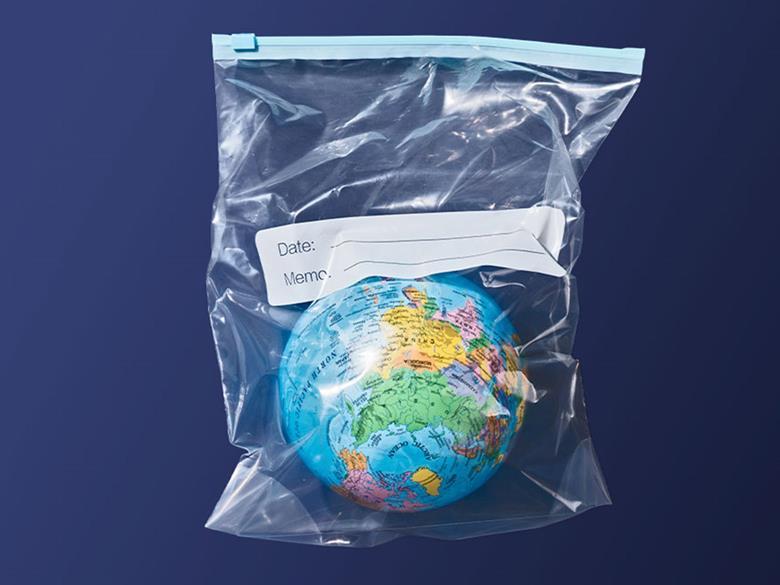

Recycling businesses in Togo and Nigeria, bioplastics made from invasive plants from Lake Victoria, and a process of waste conversion to create safe and affordable cooking fuel in Kenya are amongst the recipients of £4 million as part of the Afri-Plastics Challenge, which aims to cut down on plastic pollution in Africa.

Run by innovation prize experts Challenge Works and funded by the government of Canada, the Afri-Plastics Challenge initiative aims to reduce amount of plastic waste both on land and in the ocean in and around the African continent.

Amongst the companies receiving funding in Strand 1, Green Industry Plast – Togo, based in Lomé, involves the foundation of collection units and sorting facilities for plastic waste in collaboration with local authorities in Togo’s major cities. As well as reducing the amount of pollution in the natural environment, the solution aims to utilise conversion machinery to produce bricks, paving slabs, whiteboards for use in schools, and more.

Furthermore, it is expected to create new jobs and facilitate further education about environmentalism by recruiting and training vulnerable women and young people who no longer attend school to sort and reuse waste materials. Each town is set to be equipped with bins for selective sorting.

“Up to 40% of households in Lomédump their rubbish in the natural environment – it is a public health menace and destroying the Togolese coastal and marine ecosystem,” explains Gado Bemah, CEO of Green Industry Plast – Togo. “We are building a sustainable and effective solution to plastic waste management in Togo for an inclusive circular economy by integrating the collection, sorting, and recycling of plastic waste. A grassroots approach will result in cleaner cities and prevent water pollution.

“Our ambition is to implement and increase recycling schemes for waste plastic and to build new warehouses to increase storage capacity. We want to equip every stakeholder in the city’s living environment – from City Hall to private citizens – with the tools to recycle to improve public health and living conditions.”

Meanwhile, Chanja Datti is an in-house, technology-driven, end-to-end process for plastics waste recycling involving the direct purchase of collected plastic from waste pickers and aggregators in an effort to support marginalised groups. With a series of recycling hubs currently operating across Abuja, the purchased waste is transferred to Chanja Datti’s aggregation, processing, and manufacturing plant, where it is processed into post-consumer recycled plastics to be sold to manufacturers.

Olufunto Boroffice, CEO of Chanja Datti, continues:“Over 64 million tons of waste is generated annually in Nigeria; unfortunately, only 10-15% of this is collected and recycled, with approximately 200,000 tons of plastic waste entering our water-bodies annually.

“Our aim is to establish a series of recycling hubs across northern Nigeria, building on our success in Abuja. The collected plastics will be processed and sold as post-consumer recycled plastics to plastics manufacturers for use by large bottle-to-bottle manufacturing companies.”

Mega Gas is based in Nairobi, Kenya, and seeks to convert unsorted plastic waste, especially polyethylene, into clean and affordable cooking gas through a patented process. Its thermal cracking process of distillation and compression is thought to produce clean gaseous fuel without generating emissions, residue, or further pollution, with the fuel harvested in metal cylinders for easy use and handling.

“4.2 million people die annually from indoor pollution because they do not have access to clean and affordable energy; meanwhile, humanity produces about 300 million tons of plastic waste each year, with much of this ending up in our rivers and polluting our planet,” says CEO Peter Njeri. “Mega Gas aims to solve both of these problems by recycling plastic waste into clean, affordable energy source. We use a patented thermal cracking process that converts plastic waste into a gas which is harvested, compressed into cylinders, and sold at affordable prices.”

In Strand 2, Chemolex’s Biopactic solution claims to be a recyclable, reusable, and 100% biodegradable material that hopes to replace single-use plastic polymers in food and product packaging. Produced from invasive water hyacinth plants that grow in Lake Victoria, Kenya, the solution hopes to cut down on the environmental, economic, and health impacts of their aggressive growth as well as cutting down on plastic waste.

“We supply 100% biodegradable and sustainable bioplastic material – Biopactic – that is a superior alternative to the single use plastic polymers used in food and product packaging and diaper manufacturing,” says Clifford Okoth Owino, founder and CEO of Chemolex. “Our patented precision bio-conversion technology enables us to sustainably utilise the invasive water hyacinth plants for bioplastic production to replace the use of these single-use plastics.

“Over the course of the last year, we have completed market research and analysis for our products and have started commercial production and supply. We currently supply more than 8,000 pieces of biodegradable bread bags and other customised packaging solutions across the Kenyan market. Chemolex has also developed biodegradable diapers and sanitary pads which are currently available in the Kenyan market.”

As a Strand 3 winner, Ukwenza VR reaches out to Kenyan consumers via virtual reality technology to demonstrate the journey taken by discarded plastic at end of life. This is hoped to raise awareness of the environmental damage caused by plastic waste and encourage consumers to dispose of their plastic waste effectively.

“Plastic pollution is a challenge that affects many cities and communities in Kenya,” says Ukwenza VR co-founder Njeri Ndonga. “The main cause of this in informal settlements is an over-reliance on plastic and a lack of adequate waste management systems. There is also inadequate sensitisation within communities to the effects of plastic waste on their lives and environment.

“Schools generate a significant amount of waste. School children lack skills, knowledge, and support because they have no basic formal or comprehensive environmental curriculum that teaches about plastic waste. While the current school curriculum touches on plastics, it is not enough to bring about behaviour change without an investment in their supplementary education.

“We work to bridge the learning gap by providing immersive and engaging educational virtual reality (VR) content that complements the current educational systems in urban areas in Kenya. VR encourages problem solving, decision-making and behaviour change in both children and adults.”

Additionally, Baus Taka Enterprise’s #StopPlasticPollution Campaign is intended to promote the segregation of plastic waste from its source and spread awareness of responsible waste management practices. Its mobile app hosts competitions on plastic segregation with monetary incentives, as well as offering redeemable points for medical services in partnership with health clinics.

According to co-founder and CEO Dr Tayba Hatimy, “Mombasa is Kenya’s second largest city and East Africa’s largest port. It generates an estimated 708 tons of waste daily, 42 tons of which is plastic waste, of which 44% is uncollected. Households in Mombasa do not have access to public waste management services, and so turn to informal waste managers, who often illegally dump mixed waste. This waste then makes its way into Mombasa’s rivers and oceans.

“The #StopPlasticPollution Campaign addresses this plastic mismanagement challenge at the source, to reduce marine plastic pollution. The Baus Taka mobile app is a platform to collect data on waste, and provide monetary incentives to members of the community who sort and trade their used plastic, which is then collected by Baus Taka and transported to recycling centres. Users are rewarded with points which can be traded for health services at partner health clinics, or access to entrepreneurship training to support their success as plastic waste managers.”

In Europe, an AI-based waste sorting solution from Lixo and a reusable alternative for e-commerce packaging from Rhinopaq recently received their own funding as part of Circular Valley’s Circular Economy Accelerator Programme.

Bionanopolys has also launched an open call to give five projects fully-funded access to its fourteen upgraded pilot plants and complementary services for the development, testing, and/or scaling up of bionanomaterials.

Source: