The purpose of packaging analysis is two-fold:

1. To prevent external contamination from entering the product to be ingested.

2. To avoid having the packaging become a source of contamination to people, animals, and the environment.

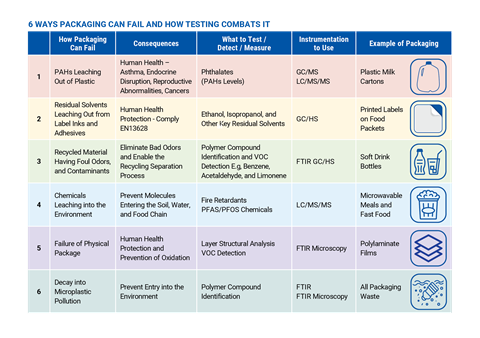

Packaging has become well-regulated and governmentally legislated with basic requirements that help protect consumers by ensuring the integrity and safety of ingested items. As indicated in the table, when packaging fails, serious and far-reaching problems can follow suit.

Most food packaging is multi-layered and made of laminates. Barrier layers within packaging can ensure food safety, add shelf-life, and can create an oxygen, aroma, and flavor barrier. Layered food packaging protects food, improves manufacturing operations, reduces damage and waste, enables better retail and food service storage, and more.

However, plastic packaging adds just as many layers of concern. In recent decades, it has been discovered that chemical compounds and microplastics can leach out of the packaging. As a result, scientists and government departments are collaborating to prevent leaching and other dangerous issues from occurring through the analysis of chemical structure, temperature, storage time, humidity, physical characteristics, and other factors.

- For greater depth with data points on such analyses – read this Whitepaper on analytical testing during manufacture and recycling.

Food regulation continues to improve and evolve. Researchers and regulators are actively working together to identify leachable compounds and determine acceptable levels for the safety of human health, animal health, and the environment. New threats are likely to emerge. For example, PFAS started as an environmental issue and have rapidly evolved into a food safety issue.

Learning how to better test, detect, and measure plastic packaging will surely continue to evolve, creating real-world solutions to this ongoing concern.

- Download the companion step-by-step Instrument Buyers Guide if you want to better understand which PerkinElmer instruments could best meet your testing needs.

- Watch how research is helping to advance possibilities for recyclate polymer material in PerkinElmer’s Video at JKU Johannes Kepler University – contributing to clean energy transitions and sustainability.

You can learn more about PerkinElmer laboratory solutions for polymers and packaging at https://www.perkinelmer.com/.

Source:

https://packagingeurope.com/6-ways-packaging-can-fail-and-how-to-prevent-it