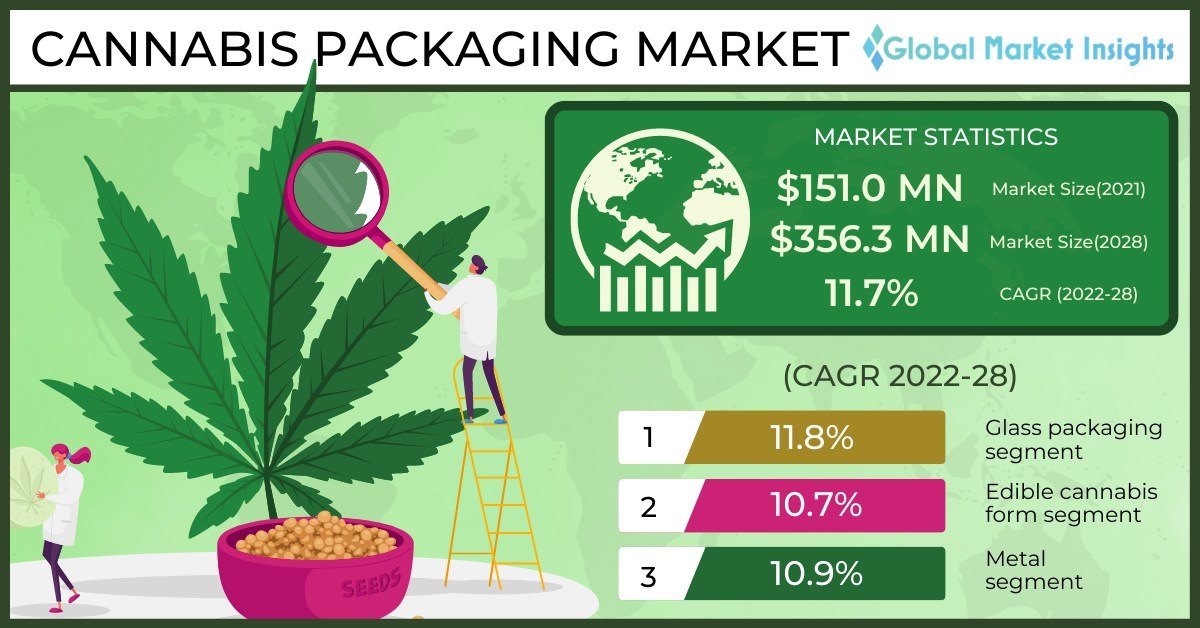

As per the report published by Global Market Insights Inc., the global Cannabis Packaging Market was estimated at USD 151 million in 2021 and is estimated to surpass a valuation of $356.3 million by 2028, progressing at a CAGR of 11.7% from 2022 to 2028. This report offers a detailed analysis of wavering market trends, drivers & opportunities, top winning strategies, competitive scenarios, major investment pockets, and market size & estimations.

Growing awareness of the positive effects of cannabis in medical treatments, along with the formulation of numerous drugs, has boosted the consumption of cannabis ingredients in the medical industry, which is propelling market growth. For instance, the U.S. Food and Drug Administration (FDA) approved the usage of medications prepared using Tetrahydrocannabinol (THC) like nabilone and dronabinol to treat nausea in patients undertaking chemotherapy as well as to enhance appetite in patients with Acquired Immune Deficiency Syndrome (AIDS) who showcase wasting syndrome. Likewise, consuming cannabis in the form of smoking or a beverage causes intoxication & euphoria without harm, which has led numerous countries to legalize it for recreational purposes. Therefore, rising demand for cannabis products in these regions is anticipated to significantly drive the cannabis packaging market revenue over the forecast timespan.

Cannabidiol oil offers many advantages, such as treating pain & some mental health disorders, reducing cancer-related symptoms, avoiding side effects of cancer treatment like vomiting, nausea, and pain, and benefiting the heart & circulatory system. Cannabidiol oil is usually packaged in glass material, which is bolstering the demand for glass cannabis packaging. Glass jars or bottles are airtight, completely moisture-resistant, and odor-resistant storage solutions that are manufactured from high-grade hygienic glass, which would further fuel product adoption. The glass material segment is set to progress at a CAGR of over 11.8% through the assessment period.

Meanwhile, the plastics material segment dominated the cannabis packaging market in 2021 and is slated to register notable revenue growth through 2028. Plastic packaging is considerably economical, cost-effective, and sturdier, which is foreseen to impel segmental growth in the forthcoming years.

Key reasons for cannabis packaging market growth:

- Increasing legalization of cannabis for medical use.

- Surging adoption of glass in cannabis packaging.

- Growing consumer preference for cannabis flower.

2028 forecasts show the “flower” segment retaining its dominance:

Based on cannabis form, the cannabis packaging industry share from the flower segment is expected to grow at a CAGR of more than 12.0% from 2022 to 2028. Prevalent legalization of cannabis for medical purposes in major states of the U.S., such as Florida, Colorado, California, and Washington, has aided the uptake of cannabis flower, which is likely to impel segmental growth over the forthcoming years.

North America to continue its top status in terms of revenue: In the regional landscape, the North America cannabis packaging market is projected to hold approximately 93.0% market share by 2028. Rising government support and initiatives in several U.S. states have led to the legalization of cannabis. The U.S. offers lucrative opportunities for many start-ups to enter the regional market and provide cannabis packaging services at competitive prices to fulfill the mounting demand. Factors like these are estimated to enhance cannabis packaging market growth in the future.

Impact of COVID-19 pandemic on cannabis packaging market

Declaration of lockdowns after the COVID-19 outbreak boosted the uptake of cannabis products for both medical and recreational purposes. Several retail stores across various states of the U.S. witnessed heavy traction for cannabis products due to consumers’ fear regarding the shortage of cannabis products, which led to mass consumption of cannabis. Cannabis products reported the highest retail sales in March 2020, creating a massive demand for cannabis packaging during the COVID period.

Leading market players

Key market players analyzed in the cannabis packaging market report include Green Rush Packaging, Berry Global Inc., Cannaline Cannabis Packaging Solutions, Kaya Packaging, Max Bright Packaging Ltd, Pollen Gear, KushCo Holdings Inc., Dymapak, Drug Plastics Group, Impak Corporation, N2 Packaging, Diamond Packaging, Packaging Bee, and others.

Source:

https://www.packagingstrategies.com/articles/96956-the-cannabis-packaging-market-would-exceed-3563-million-by-2028-says-global-market-insights-inc